Home » The Process of a New Foundation: From Excavation to Certified Quality

Get Your Free Estimate

Fill out the form below. We reply within 24 hours.

ON THIS PAGE

- Foundation

The Process of a New Foundation: From Excavation to Certified Quality

A new foundation is the most important part of your home, and it’s the only part you’ll never see. When it’s done right, it quietly and reliably supports your home for generations. When it’s done wrong? It’s a catastrophic failure that can compromise the entire structure.

As a premier foundation contractor in Orange County, we often talk to clients who are (understandably) anxious about this part of their build. It’s a big, expensive, and “invisible” line item. What are you actually paying for?

You aren't just paying for concrete. You are paying for a complex, multi-stage process that ensures the “certified quality” of your home from the ground up.

Step 1: The “Blueprint” Phase (Before the Dig)

You can’t have expert foundation excavation without an expert plan. We never just show up and start digging. The first phase is all about engineering, science, and planning.

- The Geotech Report As we discussed in our article Building on Coastal Soil, it all starts with a geotechnical (or “soils”) report. This is the instruction manual for your property. It tells us what we’re building on, how deep the water table is, and what the seismic risks are.

- Engineering the Solution The Geotech report dictates the type of foundation you need. Will the soil support a post-tension slab, or do we need deep piles to bypass poor soil? The engineer specifies the exact requirements based on this data.

- Permitting & Compliance We submit this highly detailed plan to the Newport Beach building department. This proves we are adhering to all building codes and Title 24 seismic standards. Only after the city stamps this plan as “Approved” do we move a single pebble.

Step 2: Precision Foundation Excavation

This is where the physical work begins, and “precision” is the key word. We aren’t just digging a hole; we are surgically carving the earth to match the engineer’s exact specifications.

- Site Clearing & Access We clear the lot of any old structures (demolition), vegetation, or debris to establish a safe and secure site for heavy equipment.

- Laser-Level Grading Using laser-guided equipment, we “cut” the building pad. This means grading the lot to the millimeter to ensure it is perfectly level and at the correct elevation—a critical step for proper drainage.

- The “Cut” (The Dig) This is the main foundation excavation. We dig out the earth for the foundation itself, whether it's a 30-inch-deep “cut” for a slab-on-grade or deep, precise trenches for footings.

- Soil Export We haul away all the excavated soil. A typical foundation can require dozens of dump trucks to transport the “spoils” to a legal, certified dump site.

- Utility Trenching While the ground is open, we excavate smaller, precise trenches for all “underground” utilities—plumbing, sewer, electrical conduit, and gas lines.

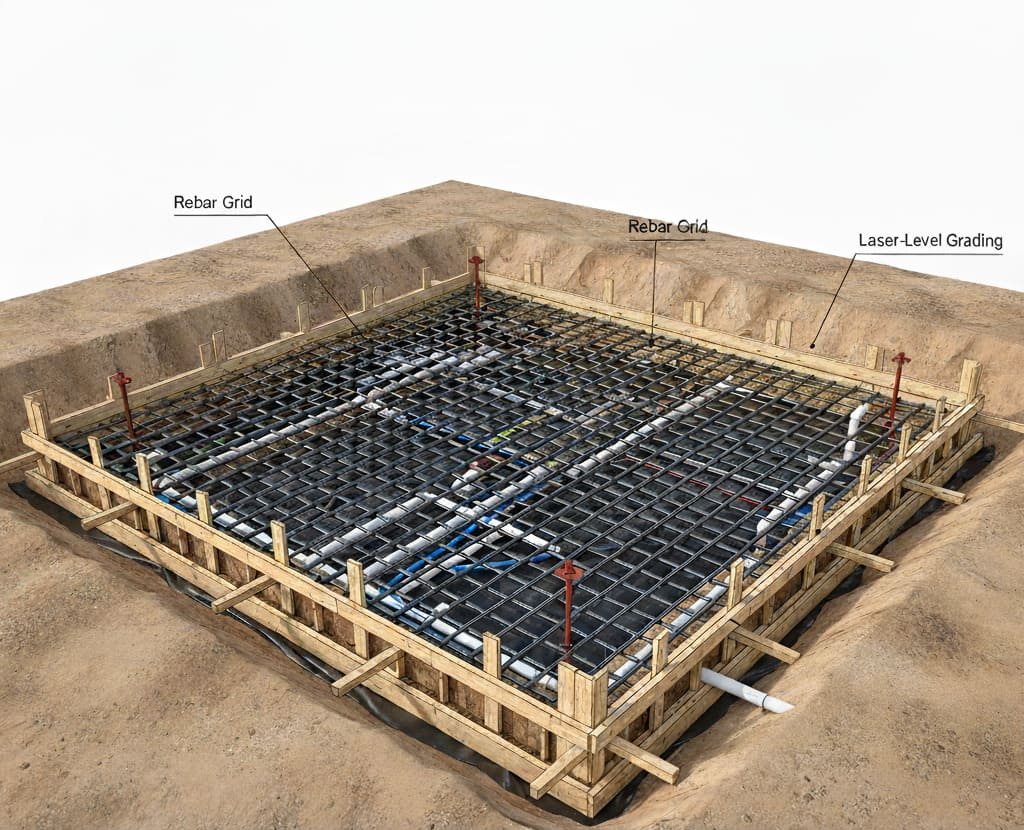

Step 3: Building the “Bones” (Rebar, Forms & Utilities)

With the hole dug, we start building the foundation inside the earth. This is where the real expertise of a foundation contractor in Orange County shines.

The Anatomy of the Pre-Pour

- Forms We build a “mold” out of wood (the forms) that will hold the wet concrete in the exact shape of the foundation.

- Utilities Our plumbers and electricians lay all under-slab pipes and conduits. This is the only chance to get this right. Every pipe must be perfectly placed, bedded in sand, and pressure-tested for leaks.

- Rebar Grid A massive, intricate skeleton of steel rebar is tied together by hand. Concrete is strong in compression but weak in tension; the rebar provides the tensile strength that holds the foundation together during seismic activity.

- Vapor Barrier We lay a thick, high-grade plastic vapor barrier to prevent ground moisture from wicking up into the slab and into your home.

Step 4: The Pour & The Cure (Certified Quality)

This is “the big day.” It’s a highly coordinated, all-at-once event.

- The Pour Dozens of concrete trucks arrive in a staggered, non-stop flow. We pump thousands of pounds of engineered concrete mix (designed for a specific PSI strength) into the forms.

- Vibration As the concrete is poured, our team uses mechanical vibrators to shake the wet mix, ensuring it flows into every corner and removes air pockets. A foundation full of air pockets is a weak foundation.

- Finishing Our best finishers “strike” the concrete with long, flat tools, making it perfectly level and smooth.

- The Cure The foundation is not “done” when the trucks leave. For the next 7-28 days, the concrete is “curing”—a chemical reaction that gives it strength. We manage this process (often by flood-curing) to ensure it reaches maximum design strength.

Step 5: The Final Certification

This is the final step that delivers our certified foundation services.

If it’s a post-tension slab, we return to “stress” the cables, locking the slab into its super-strong compressed state. But the real certification comes from the city. Inspectors visit the site multiple times to verify code compliance.

Our commitment as your Newport Beach foundation contractor is to deliver a product that passes every inspection, the first time, with zero compromises. From the first soil test to the final inspector’s signature, that is the process you’re investing in.

Planning a new build or a major remodel? Contact Gaga US Construction today. Let’s start your project on a foundation of trust and expertise.

Frequently Asked Questions

Let's Build Something Lasting

Stop searching and start building. If you are ready to secure your home and boost your curb appeal, let’s talk. We are currently booking for the 2026 season.